Calibration of a rotary evaporator is a mandatory task to ensure good performance and operational safety in the laboratory. There are several methods to calibrate a rotary evaporator and they should be chosen based on the application, complexity and economic requirements. Researchers have tested and compared several ways to calibrate a rotary evaporator to determine which offers the greatest efficiency in different situations.

In a recent study, methods of calibrating a rotary evaporator by measuring steam temperature, steam pressure and solution concentration were compared. Vapor temperature was monitored using an infrared thermograph system, which allowed an accurate and reliable measurement. The vapor pressure was obtained by means of a vacuum pump, and indicates the degree of pressure at which the vapor passes through the equipment and how this influences the evaporation efficiency. The concentration of the solution was determined by means of a glucose and serum analyzer with an infrared detector.

Aspects to take into account when calibrating a Rotavaporator

The results of the study showed that the most effective method for calibrating a rotary evaporator depended on the specific product being measured. Vapor temperature was the most accurate parameter for measuring liquids with a simple composition, while vapor pressure was more reliable in complex situations. Measuring solution concentration with an infrared detector was especially useful for liquids of high densities or highly fractionated liquids.

It was also interesting to find that using all three methods to calibrate a rotary evaporator at the same time offered the highest efficiency for most products. This can be beneficial for laboratories faced with the task of calibrating equipment for different applications. In contrast, using either method individually was only effective for single products.

Process to be performed by the operator when calibrating the equipment

The operator must correctly calibrate a rotary evaporator before using it, to ensure maximum safety and obtain the best results. There are also some common mistakes that some operators make when calibrating a rotary evaporator.

It is also essential to have an operator check the device for leaks. This is important because if leaks are present, the equipment will operate inefficiently and could cause damage to the materials involved. One way to avoid this mistake is to make sure the equipment is hermetically sealed. This will help keep the equipment working properly without leaking.

First, it is important to identify the amount of steam the equipment can generate. This can be accomplished by measuring the pressure and temperature inside the unit. These measurements are critical to the correct calibration of a rotary evaporator. If they are not measured correctly, the equipment can move above its allowable limit, resulting in higher losses and even damage to the equipment and the operator.

Mistakes when calibrating a rotary evaporator

A common mistake operators make is not calibrating the rotary evaporator before using it for the first time. This is because certain factors such as pressure or temperature changes in the room in which the equipment is being used are not taken into account, which can affect the way the equipment works. In this way, the rotary evaporator will not heat or cool the liquids at an optimal rate, which can cause process losses.

Another common mistake when calibrating a rotary evaporator is to underestimate the amount of liquid needed to run the process. By using less liquid than necessary, the equipment will not optimally heat or cool the liquids involved, which could result in longer times to achieve the desired results. It is important to determine the necessary amount of liquid before starting the calibration process.

In addition to the errors mentioned above, it should be kept in mind that the equipment must always be in perfect condition to ensure its safety and operability. This is achieved by regular cleaning and replacing damaged parts. This will help to keep the equipment working in optimal conditions.

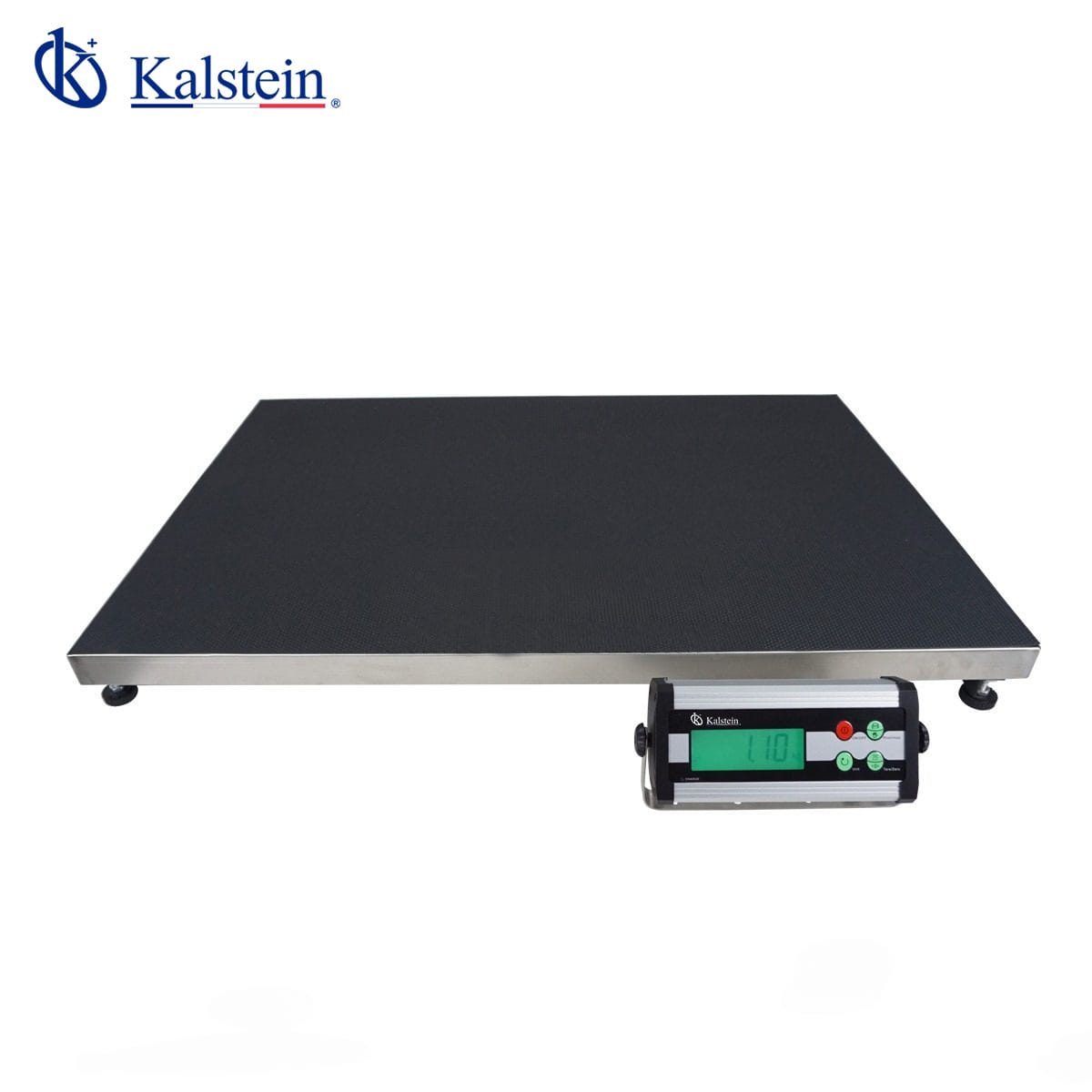

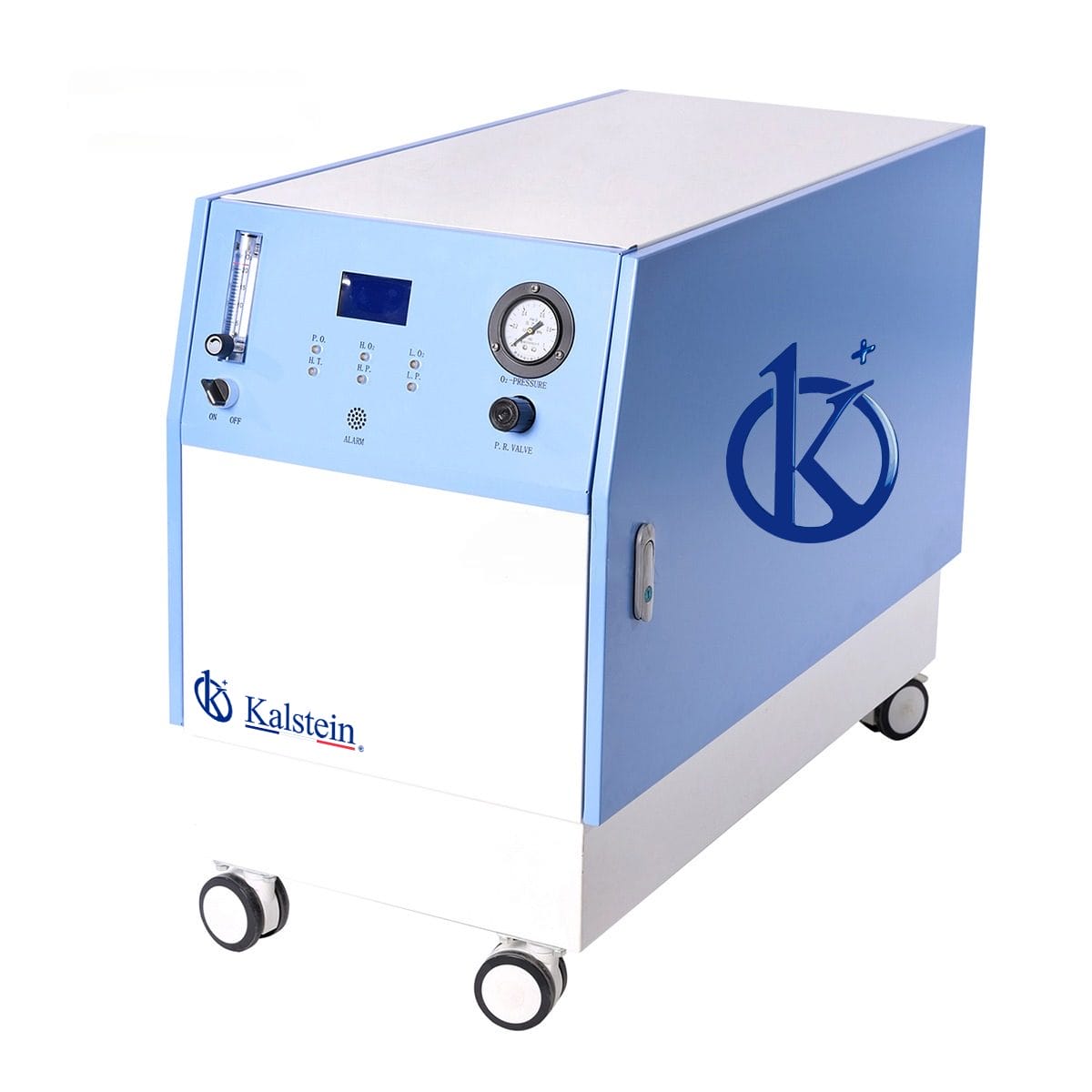

What Kalstein offers you

A YR series that you will find in HERE where you can review each design and feature that meets the needs of your laboratory, Kalstein offers the best prices in the market, and ensures an efficient purchasing process, where you will have the advice of specialists who will answer all your questions.