Product Description

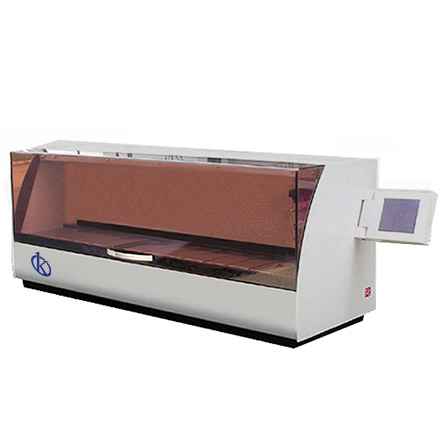

The YR435 Automatic Fabric Dyeer is an advanced laboratory instrument designed to meet the needs of contemporary textile testing environments. This innovative device offers precise control over fabric dyeing processes, enhancing both productivity and quality assurance in textile laboratories. With 14 processing cups, including 12 reagent cups and specific stations for washing and drying, the YR435 maximizes efficiency by allowing simultaneous processing of samples.

Each station’s processing time is highly customizable, ranging from 0 seconds to 59 minutes and 59 seconds, providing flexibility according to diverse experimental requirements. The individual cup capacity is 1500ml, and the device can efficiently handle up to 72 slides at once, emphasizing its capability for batch-processing.

The standard working voltage for the YR435 Automatic Fabric Dyeer is AC 220V ± 10% 50Hz, with an alternative model for AC110V ± 10% 60Hz, catering to global electrical standards. Operating at a power requirement of 500W, the device maintains operation efficiency while being energy conscious. The physical dimensions of 1180 × 420 × 470 mm, combined with a net weight of 70 kg, ensure that it fits seamlessly into lab environments.

| Model | YR435 |

| Number of processing cups | 14 (12 reagent cups, the 8th station for washing and the first drying station) |

| Processing time duration for each station | Adjustable within 0 min 0 s – 59 min 59 s for each station |

| Individual cup capacity | 1500ml |

| Number of slides to be processed at the same time | 72 pieces |

| Working voltage | AC 220V ± 10% 50Hz (standard model); AC110V ± 10% 60Hz |

| Power requirements | 500W |

| Dimensions | 1180 × 420 × 470 mm (W × D × H) |

| Net Weight | 70kg |

Market Price

The market position of the YR435 Automatic Fabric Dyeer reflects its advanced capabilities and robust performance. This cutting-edge piece of equipment is competitively priced between USD 8000 and USD 9200. This range ensures it remains accessible to laboratories seeking to elevate their operational standards without compromising on quality.

Frequently Asked Questions

What is the primary use of the YR435 Automatic Fabric Dyeer?

The YR435 is primarily used for precise dyeing of fabric samples and other textile materials in laboratory settings, enhancing process control and experimental accuracy.

How many slides can be processed simultaneously?

The YR435 can process up to 72 slides at once, making it an ideal choice for laboratories that require high throughput.

What are the customizable features of this machine?

The processing time for each station is adjustable from 0 seconds to almost an hour, offering significant flexibility based on specific laboratory needs.

Advantages and Disadvantages

Advantages: The YR435 stands out due to its high capacity, precision, and flexibility. Its ability to handle 72 slides at once considerably boosts laboratory throughput, while the customizable processing times allow for tailored experimental setups.

Disadvantages: On the downside, its relatively large size might pose challenges in smaller laboratory spaces, and the need for specialized electrical connections may require additional setup efforts in certain locations.

Use of the Product in the Field

In practical scenarios, the YR435 Automatic Fabric Dyeer is used extensively in textile laboratories worldwide. Researchers and technicians leverage its precise time settings to conduct experiments that require exact dyeing durations. Its robust capacity plays a crucial role in research projects that demand the simultaneous processing of multiple fabric samples, thus enhancing the efficiency of textile and fabric testing.

Being fully automated, the YR435 minimizes manual intervention, allowing lab personnel to focus on analysis and interpretation rather than operational logistics. This feature significantly reduces human error and improves the overall reliability of the results obtained.

Recommendations

To maximize the performance and longevity of the YR435 Automatic Fabric Dyeer, regular maintenance and calibration checks should be conducted. It is recommended to adhere strictly to the manufacturer’s guidelines regarding setup and operational procedures. Laboratories should also ensure that operators are trained appropriately to exploit the full range of features offered by the machine.

Furthermore, integrating the YR435 into a comprehensive fabric analysis program can significantly enhance research quality and output efficacy. Lab managers might consider exploring additional Kalstein products to complement the YR435, thus expanding testing capabilities and establishing a well-rounded research toolkit.

If you are looking for a fusion of innovation and quality, you have come to the right place. At Kalstein, we offer you the luxury of exploring our exclusive catalog of laboratory equipment. We manufacture each piece of equipment with a level of excellence. Our intuitive and agile online purchasing channels are designed for your convenience, ensuring the most user-friendly prices. Don’t hesitate any longer; we bring life to science, and it’s time to become part of our community. https://kalstein.net/en/product/yr435-automatic-fabric-dyeer/.