The shelf life of a food product can be defined as the period during which, this food is acceptable and meets quality specifications. On the other hand, most foods show deterioration of these specifications, over time. This depends on their constitution and the conditions under which they are stored.

It is necessary to evaluate the shelf life of manufactured foods and beverages, in order to know for how long the commercial value of these products will be maintained, and thus meet the needs and expectations of consumers.

The shelf-life test allows us to obtain information about when the food product has different characteristics than those shown at the time of its manufacture, and that make it unacceptable to the consumer. The analysis of the shelf-life of food uses a combination of analytical, microbiological and sensory evaluations for the assessment of aging and degradation of a product. This information allows the identification of expiry dates and preferred consumption.

How can we estimate the shelf life of a food?

In general, the life span is estimated through two different procedures in the stability test: real-time stability test and accelerated stability test. In real-time stability testing, a product is stored under recommended storage conditions for a time equal to or longer than the expected shelf life and is monitored until it is within specification. In the accelerated stability tests, the product is stored under high stress conditions for the variables temperature, humidity and pH.

Conducting a real-time stability test is a challenge for the food and beverage industry, because the test duration is equal to or longer than the expected product lifetime, so it can last up to a year or longer. In addition, quality parameters should be regularly monitored during the execution of the assessment. This requires a significant amount of sample and may increase the costs of analysis.

For this reason, accelerated testing is used, where the storage conditions are intended to increase the speed of any change and therefore reduce the study time.

How can a stability test be performed for food products?

Food stability tests can be done with climate chambers. Because these equipment simulate a variety of temperature, humidity, and lighting conditions, they are useful for accelerated stability testing.

Periodic chemical, physical and microbiological analyzes should be performed during the test, until the degradation of the food products is evident, through physical and sensory changes, e.g. mold formation, color changes, water separation, odor emanation, among others.

In addition to providing information on the stability of the product over time, climatic chambers, through accelerated stability testing, allow us to identify the safety of food under inadequate storage conditions, eliminate errors in the preliminary stages of product development and manufacture, and facilitate the assessment of the suitability of the product packaging.

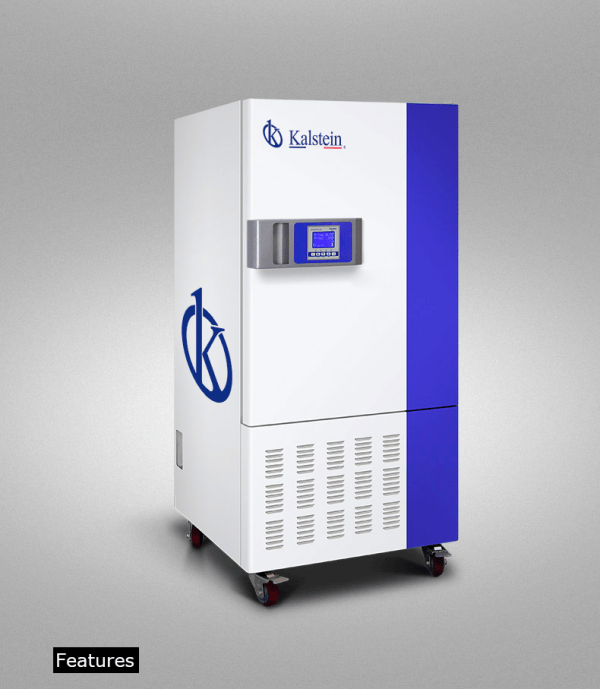

Kalstein climate chambers

At Kalstein we have a wide variety of YR series climate chambers for sale, whose characteristics depend on the model you choose. They have an efficient insulation system, which reduces energy consumption. They also have an ALLGENT™ humidification system that allows quality atomizations. In addition, they have an ALLFLOW air current system, which allows to maintain temperature and humidity in a continuous and stable manner, guaranteeing a favorable environment for testing and testing. Kalstein climate chambers feature an ergonomic design that offers operational comfort, dot matrix LCD screen, double layer insulation design, and an internal door that allows easy observation of samples. For more information on the Kalstein climate chambers, visit the HERE