Viscometers are fundamental tools in various scientific and technological fields. From laboratory research to medical applications, these devices significantly contribute to the accuracy and efficiency of liquid viscosity measurements. In this article, we will detail the benefits of the viscometer, its unique features, and how it solves specific problems for users.

Precision in Medical Diagnostics

Medical innovation greatly benefits from the use of viscometers. The viscosity of biological fluids, such as blood and plasma, is crucial for accurate and personalized diagnoses. Measuring viscosity provides vital information about patient health and can identify issues like dehydration, cardiovascular diseases, and clotting disorders. A highly precise viscometer can detect minor variations in viscosity, helping doctors make early diagnoses and customize treatments.

Furthermore, advanced viscometers allow for repeated testing with great accuracy, which is essential for monitoring disease progress or treatment efficacy. The ability to obtain consistent and reliable data reduces margin of error and increases confidence in medical diagnosis.

Improvements in Drug Formulation

In the pharmaceutical industry, lab research uses viscometers to ensure the quality and stability of drugs. Viscosity affects drug absorption and release time in the body. By measuring and controlling viscosity, scientists can design more effective and safer drugs, optimizing their therapeutic performance.

The capability to adjust viscosity as needed also allows pharmacists to develop multiple forms of the same drug, such as tablets, suspensions, and gels, each with specific characteristics based on patient needs. This adaptability is essential to ensure each patient receives the most suitable treatment.

Diversity of Measurement Methods

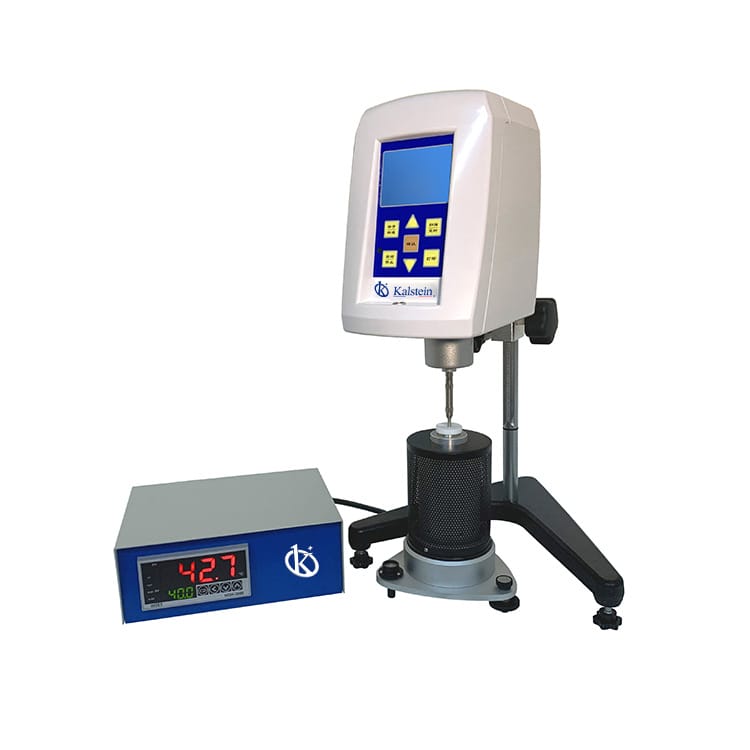

Viscometers offer a range of methods to measure viscosity, adapting for different types of liquids and precision needs. Among the most common methods are the falling tube viscometer, the capillary viscometer, the rotational viscometer, and the vibrational viscometer. Each of these methods provides unique advantages that can be leveraged depending on the type of analysis needed.

For example, capillary viscometers are ideal for measuring viscosity of low-viscosity liquids, such as solvents and aqueous solutions. Conversely, rotational viscometers are more suitable for higher viscosity liquids, like oils and syrups, providing a wide range of applications across diverse industries. This versatility ensures there is always a suitable tool for every need in laboratory research.

Digital Technology and Automation

The modernization of viscometers has led to the integration of digital technology and automated systems. Modern viscometers often come equipped with touchscreens, data storage, and network connectivity, which streamline data collection and analysis efficiently. Automation reduces the time and human effort required to perform measurements, increasing lab productivity.

Additionally, digital technology allows greater precision and repeatability in measurements. Automated devices can perform multiple tests in rapid succession, minimizing human errors and offering consistent results. Digitization also enables more in-depth data analysis and the possibility of integration with other laboratory information management systems.

Quality Control in Industrial Production

In industrial production, especially in the manufacturing of products like paints, cosmetics, and food, viscosity control is essential to ensure the quality of the final product. Viscometers provide necessary measurements to ensure products meet established standards and have uniform consistency.

For example, in paint production, incorrect viscosity can affect paint application and drying, adversely impacting its quality and durability. Viscometers allow real-time adjustments of chemical mixes, preventing defective products and reducing waste. This not only improves the final product quality but also optimizes production costs.

Engineering and Material Development

In the field of engineering and material development, viscosity plays a crucial role in the study of new compounds and materials. Engineers use viscometers to study rheological properties of novel materials, allowing for more efficient and effective design of innovative products.

For instance, in the development of new polymers or composite materials, viscosity can affect their processability and the subsequent mechanical properties of the material. Measuring and controlling viscosity during the research and development phase can lead to the creation of materials with better physical and chemical properties, impacting a wide range of industrial applications, from automotive to construction.

Analysis and Characterization of Liquids

Laboratory research is not complete without a rigorous analysis of the properties of the involved liquids. Viscometers are indispensable tools for detailed characterization of solutions and mixtures, providing critical data on their behavior under different conditions.

For example, in polymer chemistry, the viscosity of a polymer solution can reveal information about chain length and polymer molecular weight. This type of information is essential for investigating the basic properties of the material and its application in commercial products. The ability to obtain precise and reliable data is key to advancing scientific and technological research.

Innovation in Biotechnology and Nanotechnology

In emerging fields like biotechnology and nanotechnology, viscometers enable the measurement of viscosity of solutions on extremely small scales, providing crucial data for the development of new technologies. This data can be used to design nanoparticles, enzymes, proteins, and other biological materials, which can revolutionize industries such as medicine, energy, and the environment.

For example, in creating nanomedicines, the viscosity of solutions can influence the stability and effectiveness of nanoparticles in the body. Measuring and adjusting viscosity is essential to ensure these medicines work optimally, offering new opportunities for the treatment of complex diseases.

Identifying Specific User Needs

Choosing the right viscometer depends on the specific needs of users and planned applications. It is essential to consider factors such as the viscosity range to be measured, the types of liquids to analyze, and the degree of precision required. Some viscometers are better suited for low-viscosity liquids, while others are designed to handle more viscous materials.

Additionally, it’s important to consider whether automation and digitization capabilities are needed. Modern viscometers offer advanced options like data storage, integration with lab management systems, and automated operation, which can benefit high-productivity, precision labs.

Evaluating Manufacturer Quality and Support

The quality of the viscometer and the support offered by the manufacturer are crucial factors to consider. It’s essential to choose recognized and reliable brands that offer warranties, maintenance, and calibration services to ensure the device operates correctly over time. In addition, good technical support can be invaluable in resolving any issues that may arise during viscometer use.

Researching user reviews and consulting with experts can be helpful in making an informed decision. A high-quality viscometer may be a significant investment, but the benefits in terms of precision, efficiency, and confidence in the results justify the cost.

Integration with Industry 4.0 Technologies

With the advancement of Industry 4.0, viscometers are evolving to integrate with technologies like Internet of Things (IoT), artificial intelligence, and big data analysis. These innovations will enable even greater optimization in viscosity measurement and control, offering new capabilities in terms of precision and efficiency.

For example, viscometers equipped with IoT sensors can send real-time data to centralized systems, allowing continuous monitoring and automatic adjustments in industrial processes. Artificial intelligence can use this data to predict and prevent issues before they occur, improving quality and reducing operational costs.

Advancements in Medical and Scientific Research

The ongoing innovation in viscometer technology promises new applications and improvements in medical and scientific research. Advancements in sensors and materials will allow viscosity measurement with unprecedented accuracy, even in extremely small or complex samples. This increased accuracy will benefit a broad range of scientific fields, from biochemistry to molecular engineering.

Additionally, these advancements can lead to the creation of new types of specialized viscometers that offer additional benefits, such as the ability to measure viscosity in extreme environments or in real-time during experiments. These new capabilities will open opportunities for more detailed and precise research, driving scientific and technological advancement.

In conclusion, viscometers are essential tools in lab research and medical innovation. Their unique benefits and features enable researchers and professionals to optimize quality, precision, and efficiency in their work, solving specific problems and providing invaluable support across numerous fields. With continuous technological evolution, the future of viscometers promises even more integrations and advancements, solidifying as key pillars in science and industry.

Craving top-quality medical equipment, ready to power up your laboratory’s efficiency? Visit https://kalstein.net/en/category-product/laboratory-line/viscometer/ to explore our high-end catalogue, packed with the best finds at the most competitive prices. Excellence is our hallmark; we innovate and manufacture high-precision equipment both reliable and durable to meet your needs. Why wait? Make your quick and secure online purchase, leap into the future of medical technology today. https://kalstein.net/en/