Description of the Product

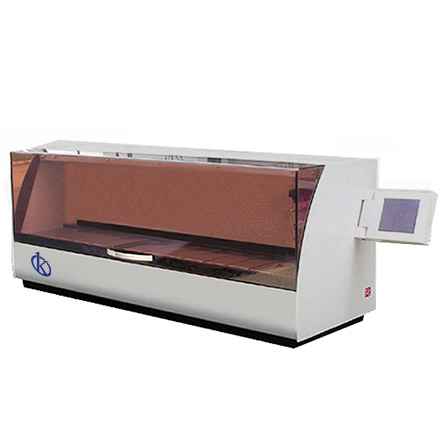

The YR435 Automatic Fabric Dyeer represents a leap forward in laboratory technology, designed to streamline and enhance fabric dyeing processes. Built to accommodate the intricate demands of textile testing, this equipment showcases a robust model engineered for precision and efficiency. Its ability to handle up to 72 slides simultaneously makes it a vital asset in high-demand settings.

The machine features 14 processing cups, which facilitate various stages of dyeing, washing, and drying, ultimately ensuring consistency in results. Each station offers processing time control adjustable from 0 seconds to nearly an hour, presenting flexible operational options. The piece supports an impressive capacity with each cup capable of holding up to 1500 ml, providing significant throughput capabilities.

| Model | YR435 |

| Number of processing cups | 14 (12 reagent cups, the 8th station for washing and the first drying station) |

| Processing time duration for each station | Adjustable within 0 min 0 s – 59 min 59 s for each station |

| Individual cup capacity | 1500ml |

| Number of slides to be processed at the same time | 72 pieces |

| Working voltage | AC 220V ± 10% 50Hz (standard model); AC110V ± 10% 60Hz |

| Power requirements | 500W |

| Dimensions | 1180 × 420 × 470 mm (W × D × H) |

| Net Weight | 70kg |

Market Price

The market for advanced fabric dyeing equipment like the YR435 reflects its sophisticated capabilities and demand in the laboratory sector. With a general price range from approximately $8000 to $9200, pricing varies depending on distributors and additional features or bundled resources. This competitive range underscores the value of investing in technology that not only meets but exceeds industry standards.

Taking a deeper dive into cost considerations, it’s essential for potential buyers to evaluate both upfront and ongoing operational costs, ensuring that the investment aligns with laboratory requirements while offering returns through enhanced productivity and efficiency.

Frequently Asked Questions

What is the main advantage of using the YR435 Automatic Fabric Dyeer?

The YR435 offers extensive capacity and versatility in handling diverse dyeing processes, significantly boosting laboratory throughput and precision in textile testing.

What maintenance does the YR435 require?

Routine cleaning and regular inspections of mechanical components are recommended to maintain optimal performance and longevity.

Can the YR435 be used for dyeing other materials besides fabric?

While primarily designed for fabric, its versatility in processing various materials may allow usage in similar contexts, provided relevant tests are conducted for compatibility.

Advantages and Disadvantages

Advantages:

- High capacity processing with up to 72 slides at once.

- Flexible processing time adjustments allow for customization per need.

- Robust design ensures long-term reliability and low maintenance.

Disadvantages:

- Requires a substantial initial investment.

- May need additional training for new users to operate effectively.

Use of the Product in the Field

In practical settings, the YR435 Automatic Fabric Dyeer finds application in laboratories focused on developing and testing textile samples. The integration of automated features reduces manual intervention, thus decreasing potential errors and enhancing test accuracy. Laboratories focusing on textile research and quality control will find this equipment indispensable in maintaining high throughput while ensuring precise control over dyeing parameters.

Thanks to its adjustable settings, the device accommodates a variety of experimental setups, allowing researchers to fine-tune parameters for optimal outcomes. The reliability and efficiency it offers play a critical role in facilitating rapid experimentation and development cycles in textile innovation.

Recommendations

To leverage the full potential of the YR435 Automatic Fabric Dyeer, laboratories are encouraged to incorporate regular training sessions for operators to maximize efficiency and ensure adherence to best practices. Conducting periodic calibration checks and following manufacturer guidelines for maintenance will further extend the service life of the equipment.

Moreover, forward-thinking labs may explore integration with other digital laboratory management systems, enhancing data capture and process automation, which can lead to further improvements in productivity and research capabilities.

If you are seeking a blend of innovation and quality, you have come to the right place. At Kalstein, we offer you the luxury of exploring our exclusive catalog of laboratory equipment. We manufacture each device with a level of excellence. Our intuitive and agile online purchase channels are designed for your convenience, ensuring the most friendly prices. Do not hesitate any longer; we bring science to life. It is time to be part of our community. https://kalstein.net/en/product/yr435-automatic-fabric-dyeer/.