Description

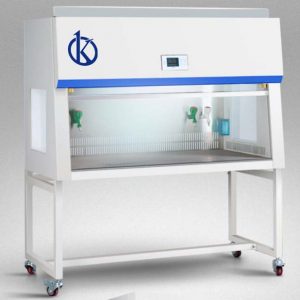

The Horizontal Laminar Flow Cabinet (Models YR06533 // YR06537) relies on our integral High-Efficiency Particulate Air (HEPA) Filter without Separator to meet the rigorous air quality demands of critical environments such as laboratories, cleanrooms, and pharmaceutical manufacturing plants. Engineered with a deep-pleat structure that eliminates traditional separators, this filter achieves and maintains an exceptional level of air purification within the cabinet’s entire work zone.

Key Features (Filter Specifications)

- Filtration Level (H14): Certified with the H14 classification, ensuring superior performance in critical applications.

- High Efficiency: Achieves an impressive filtration efficiency of equal to or greater than 99.997% for particles equal to or greater than 0.3 microns.

- Robust Construction: Capable of operating within a temperature range of up to equal to or less than 80 °C (and instantaneously up to equal to or less than 100 °C), and with humidity of up to less than 100% RH.

- Wind Speed:5 m/s

- Rated Air Volume: greater than 600 m3/h

- Initial Resistance: less than 220 Pa

- Final Resistance (Recommended): less than 500 Pa

- Humidity Resistance: less than 100% RH

Frequently Asked Questions (FAQ)

What is the H14 filter classification?

H14 is a grade within the EN 1822 standard for HEPA filters. It signifies extremely high efficiency, specifically capturing 99.997% of airborne particles 0.3 microns or larger, making it suitable for the most sensitive clean air processes within the laminar flow cabinet.

What is the recommended maximum final resistance?

The recommended maximum final resistance is less than 500 Pa. Reaching this resistance indicates that the filter is saturated with particulates and should be replaced to maintain the required air volume and efficiency within the cabinet.

Can this filter be used in high-humidity environments?

Yes, with a humidity resistance of less than 100% RH, this filter is suitable for areas with high relative humidity, provided there is no direct liquid saturation.

Advantages and Disadvantages

Advantages:

- Ultra-High Efficiency: Provides superior air purity (H14, 99.997% or greater) essential for sterile environments.

- Deep Pleat Design: Offers a large surface area for increased dust-holding capacity and a longer service life.

- Low Initial Resistance: Requires less energy for the cabinet’s fan/blower unit to operate effectively.

- Excellent Temperature/Humidity Resistance: Highly durable for various industrial conditions.

Disadvantages:

- Higher Cost: Generally more expensive than lower-efficiency filters (e.g., H13 or standard MERV).

- Handling: Requires careful handling and specialized disposal due to the captured hazardous particulates.

Product Usage in the Field

This filter is a critical component in the terminal filtration stage of the Horizontal Laminar Flow Cabinet, ensuring a clean, particle-free workspace (ISO Class 5 or better) where airborne particle control is paramount.

- Pharmaceutical and Biotechnology: Used for non-hazardous compounding, media preparation, and cell culture work.

- Hospitals and Healthcare: Essential for processes requiring a sterile work zone, such as assembly of medical devices.

- Electronics and Microelectronics: Employed to prevent contamination of delicate components during inspection or assembly.

- Laboratories: Ideal for plant tissue culture, media plate preparation, and any procedure requiring protection for the sample/product.

Recommendations

- Monitoring: Regularly monitor the differential pressure across the filter using the cabinet’s pressure gauge (Minihelic gauge) to track the buildup of resistance.

- Replacement: Replace the filter promptly when the final resistance reaches the recommended limit of less than 500 Pa to ensure optimal system performance and energy efficiency of the cabinet.

- Pre-Filtration: To extend the lifespan of this high-efficiency filter, we strongly recommend the regular maintenance and timely replacement of the pre-filter (usually included in the cabinet) to capture larger particulates.

- Installation: Installation and filter replacement should only be performed by qualified personnel, following proper cleanroom protocols to prevent damage to the filter media and ensure a leak-free seal within the cabinet.

Technical Specifications

| Model | YR06533 | YR06534 | YR06535 | YR06536 | YR06537 |

| Package Size(cm) | 93*98*109 | 113*98*109 | 133*98*109 | 163*98*109 | 187*98*109 |

| Internal Dims (mm) | 780*510*600 | 980*510*600 | 1180*510*600 | 1480*510*600 | 1720*510*600 |

| Floodlight: | LED three proof fluorescent lamp | ||||

| Table top: | SUS304 # brushed stainless steel | ||||

| Housing: | 1.0mm thick cold-rolled steel plate with epoxy resin coating sprayed on the surface | ||||

| Fan: | Built-in fan 220V, 138W, diameter 250mm | ||||

| Technical parameters of high-efficiency filter without partition | |||||

| Wind speed: | 0.5m/s | ||||

| Filter Level: | H14 | ||||

| Filtration: | ≥0.3um | ||||

| Rated air volume: | >600m³/h | ||||

| Initial resistance: | ≤220 Pa | ||||

| Final Resistance: | ≤500 Pa (recommendation) | ||||

| resistance: Temperature | ≤80°C | ||||

| Instantaneous temperature: | ≤100°C | ||||

| Humidity resistance: | ≤100%RH | ||||